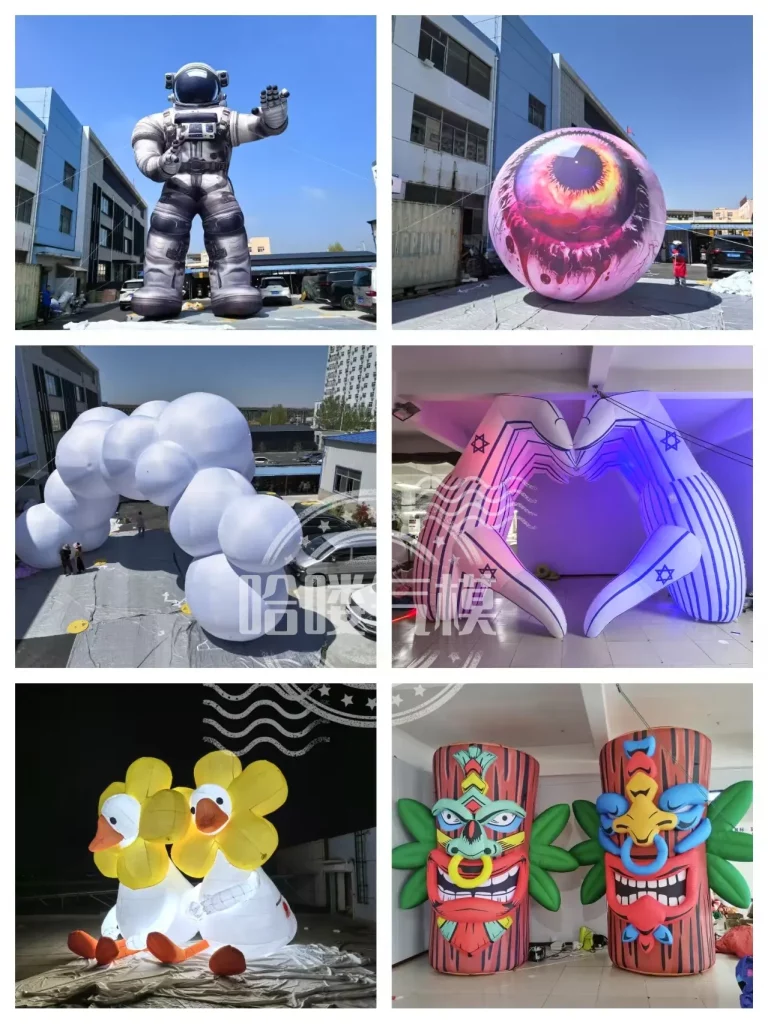

Inflatable models are extensively utilized in advertising displays, event decorations, and amusement facilities. Their manufacturing integrates creative design, cutting-edge technology, and meticulous craftsmanship. Each inflatable model undergoes numerous stringent processes. These range from the initial conceptualization of client requirements to the delivery of the final product. The stages are interconnected to guarantee exceptional product quality and visual impact.

How does an inflatable model factory operate? This article provides readers with a comprehensive overview of the production process. It details the journey from design to finished product. The following sections offer a thorough explanation.

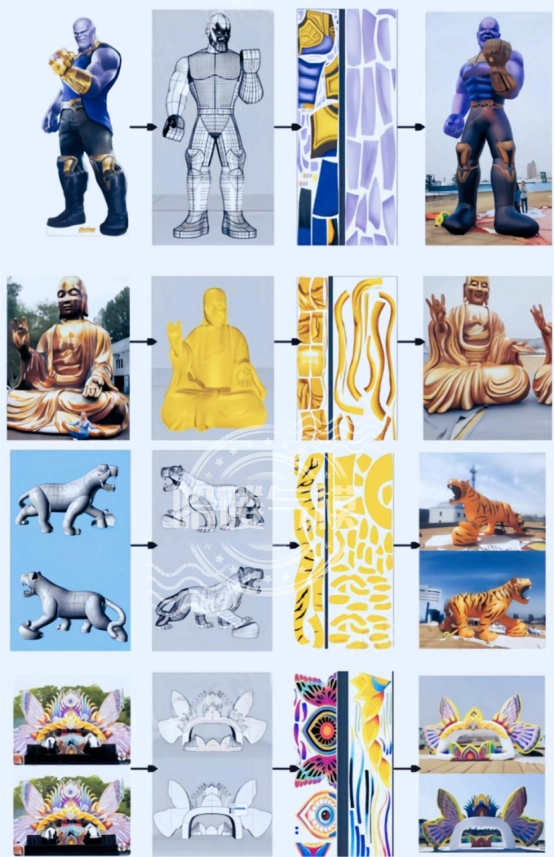

Custom Inflatable’s Design and Modeling

Upon entering the design studio, the team is engaged in ideation. Skilled designers employ software to convert clients’ concepts into accurate 3D models. The workflow encompasses: gathering client specifications, conducting team discussions to refine proposals, constructing three-dimensional models, breaking them down into two-dimensional patterns, and producing final renderings. The process is streamlined and efficient. It ensures designs are precise and aligns with expectations. Notably, designers can segment complex structures, such as the Eiffel Tower, into modular components for production.

The selection of materials is vital for durability and aesthetic appeal. HELLO INFLATABLE Model uses premium plain and twill special thermal transfer fabrics. These materials are flexible and glossy. They are also waterproof, fireproof, and resistant to tensile stress. Such properties ensure inflatables remain intact in diverse environments while delivering a striking appearance.

Custom Inflatable’s Printing and Cutting

In the printing workshop, intense heat is palpable. Four high-precision printers transfer patterns from transfer paper to fabrics at 220°C. This produces vivid colors and intricate texture effects. Adjacent laser cutting equipment trims fabrics with exceptional accuracy. Errors are virtually nonexistent. The process swiftly transforms fabrics into components ready for assembly. Workers then organize the cut fabrics. This prepares them for the sewing phase and ensures structural stability.

Custom Inflatable’s Sewing and Assembly

Assembling an inflatable demands precision in connecting various sections. Fine sewing techniques yield seamless lines while ensuring structural integrity. This results in inflatable creations with robust construction and smooth contours. In the sewing workshop, sewing machines produce rhythmic sounds. The seasoned sewing team, averaging over six years of experience, thoroughly understands design specifications. They apply double-needle sewing technology for detailed work. The stitches are even and smooth. Stitch lengths remain consistent, reflecting a high level of expertise. During sewing, workers assemble components rapidly and accurately. This ensures every seam is sturdy and long-lasting.

Custom Inflatable’s Quality Inspection

Post-sewing, products enter a rigorous quality inspection phase. Inspectors meticulously examine each item. They check if stitches are even, seams are smooth, zippers function properly, and stitch patterns are uniform. A trial inflation test follows. It replicates real-world usage conditions. Any minor imperfections are detected and must be corrected. The product is reworked until it meets all standards.

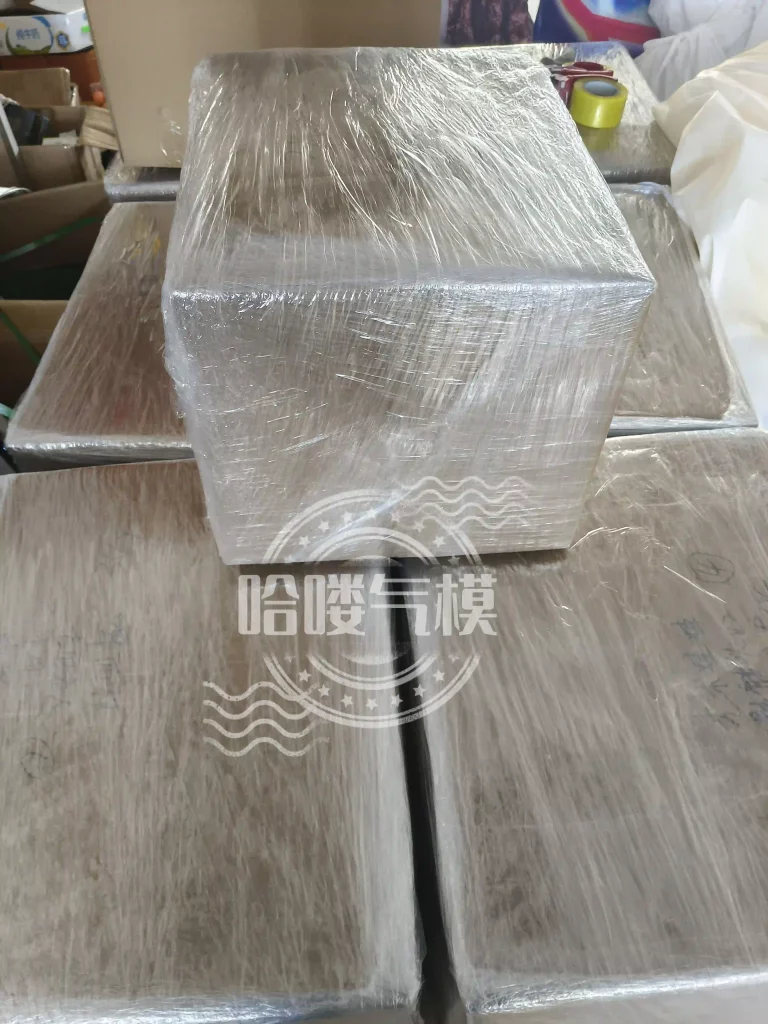

Custom Inflatable’s Packaging and Delivery

Approved inflatable models proceed to packaging. Workers compress products into compact sizes, optimizing transportation space. The items are then placed in waterproof, reinforced boxes to ensure safe transit. After numerous meticulous processes, the finished products await delivery to clients. Meeting delivery timelines is critical for client satisfaction. Close coordination between production and logistics teams ensures punctuality.

Additional Notes

Ongoing innovation enhances manufacturing techniques. The team continually explores new approaches to make inflatable designs more original and distinctive. Adopting advanced technologies boosts efficiency and broadens creative opportunities. Sustainable practices, such as using recyclable materials or reducing waste, support eco-friendly production. For insights into packaging large inflatable models (e.g., those weighing 400 kg) or undisclosed innovative designs, please share comments for further discussion. Future content will reveal additional production details.

FAQ

Q: What materials are used in custom inflatables?

A: High-quality plain twill thermal transfer fabrics are commonly used. They offer durability, flexibility, waterproofing, fireproofing, and visual appeal.

Q: How do you ensure color consistency during printing?

A: High-definition thermal transfer printing technology delivers vibrant colors with lasting vibrancy.

Q: Can I customize my inflatable’s shape or size?

A: Yes. Customization options include size, shape, color, and pattern, and they are tailored to client needs.

Q: What steps are taken during the quality inspection?

A: Inspections assess structural integrity and identify defects. Issues are promptly resolved.

Q: Are your inflatables eco-friendly?

A: Yes. We emphasize environmentally conscious practices. Waste is minimized throughout production.